Figure 5 | Modeling and Analysis for Wear Performance in Dry Sliding of Epoxy/Glass/PTW Composites Using Full Factorial Techniques

SPECIFIC WEAR RATE OF EPOXY RESIN BASED COMPOSITES REINFORCED WITH NATURAL FIBERS AND UNI-AXIAL GLASS FIBERS FOR BIO MEDICAL APP

Fretting wear rate evolution of a flat-on-flat low alloyed steel contact: A weighted friction energy formulation Abstract

Effect of tribological parameters on sliding wear and friction coefficient which relates to preload loss in tapered roller bearing | Emerald Insight

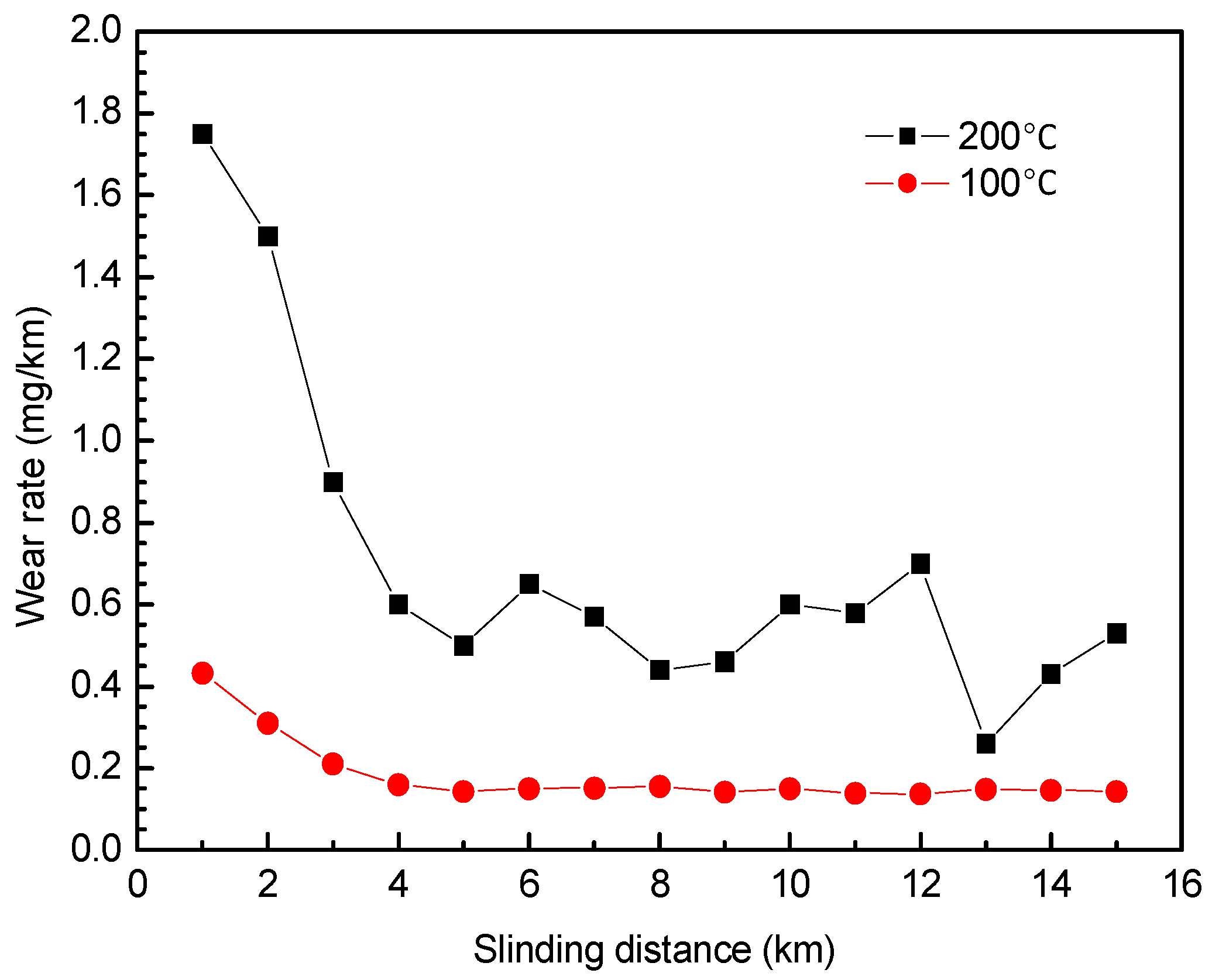

Heat treatment to improve the wear resistance of PTFE/PMMA composites - RSC Advances (RSC Publishing) DOI:10.1039/C9RA04362D

Figure 3. Wear rate of as-cast composites with different Mg additions as (a) function of time; (b) function of load : Effect of Mg on the Wear Behaviour of as-cast Al-4.5Cu-3.4Fe in-situ